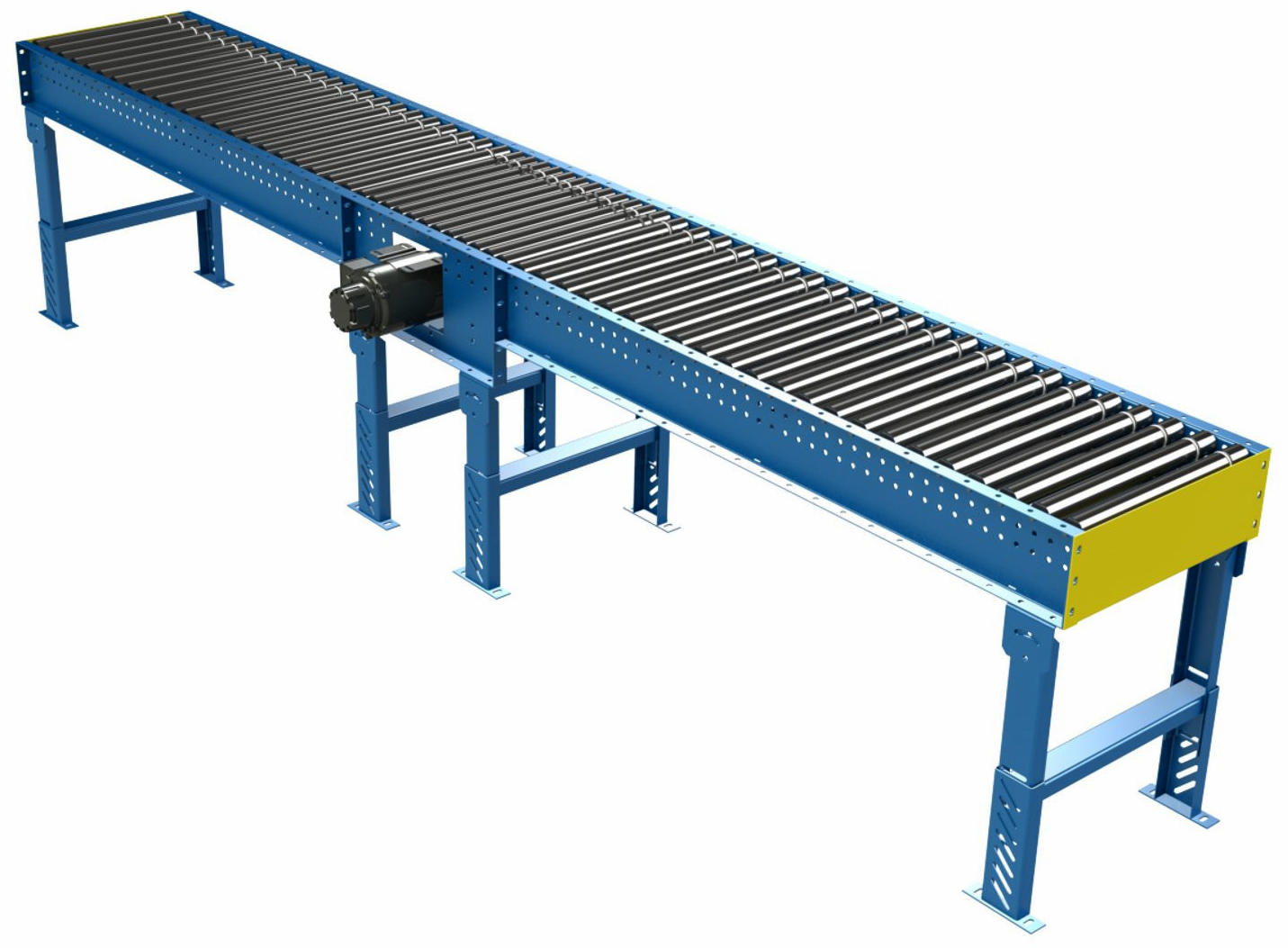

Floor Mounted Roller Conveyors

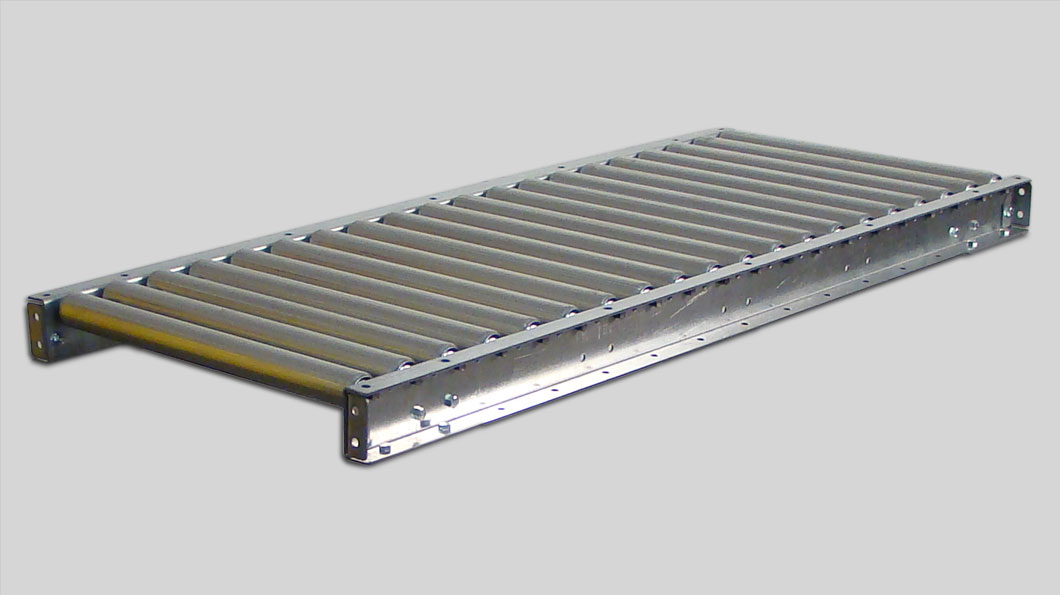

Roller conveyors consist of rollers that are mounted on a series of axles attached to rigid or telescoping frames.

Floor mounted roller conveyors. The rollers provide a stable surface for moving loads with rimmed or uneven bottoms such as drums pails pallets skids. Also known as pallet brakes these mount underneath rollers on a gravity conveyor and create friction on the rollers to control the conveyor s speed. We have a large selection of floor conveyors including gravity powered roller powered belt accumulating tabletop and slat conveyor systems. Due to the simple design shorter lengths can be used than with standard belt driven conveyor.

Common applications include being mounted atop a scissor lift or used as a transfer car bed. Ball bearings for conveyor rollers replace worn and damaged bearings or press fit bearings into tubing or pipe to create a roller. These unpowered gravity flow conveyors use a downward slope or a manual push to move loads down the line. A few more varieties are available.

Typical top of roller height is 12 30 5 cm. Roller conveyor pallet overhead floor mounted roller conveyor system description manufacturer of friction roller conveyor with 40 years of applications and miles of installed base.